Client:

Quantity:

Size:

Application:

In the dry bulk material handling world of gates and diverters, transitions are common components that are used to connect one flange on a valve to another flange on the next piece of equipment. The transitions can address custom flange to flange dimensions and can be fabricated to match special bolt patterns, tube stubs with or without sock beads, or blind flanges that allow onsite hole placement and installation. Flanges can be square, round, or rectangular. Fabricated transitions provide a wealth of flexibility for customers when installing valves with existing equipment.

In the United States, there are two primary standards for flanges. One is a CEMA flange pattern. The other is an ANSI flange pattern. CEMA stands for Conveyor Equipment Manufacturers Association and is used the most in the dry bulk industry. ANSI stands for American National Standards Institute and is easily recognized as a thick metal flange. It is used mostly for high pressure applications in the water and gas industry with 150 psig. Internationally, the metric DIN flange pattern is the most common. DIN stands for Deutsches Institut fur Normung E.V. These three organizations create many standards for manufacturing conformity, and cover a very wide range of standards and certifications.

In the dry bulk material handling industry, some equipment manufacturers adhere to CEMA, ANSI, or DIN standard flange patterns, while other manufacturers have their own flange patterns. Regardless of the pattern, sometimes a transition between the different flanges is necessary to connect the processing equipment. These transitions can include transitioning from a round flange to a square flange, transitioning from a square flange to a round flange, transitioning from a square flange of one pattern to a square flange of another pattern. And, of course, rectangular patterns may come into play.

A few typical scenarios may help explain the necessity for transitions:

Round to Square transitions

In one instance, dry bulk material is discharged from a silo into a pneumatic conveying line. Typically, the arrangement would be for a slide gate to be below the silo, with an airlock below the slide gate to meter the material into the conveying line. The silo may have a round flange, the gate may be square, and the airlock may have a square opening as well. In this case, a round to square transition would be used between the silo flange and the inlet flange of the slide gate. Round to square transitions typically add 1 1/2″ to the overall stack up height depending on size. If the flange pattern of the airlock can be matched to the slide gate, no transition would be needed between them. If not, a square to square transition would be needed.

In another example, a round to square transition may need to be used to mount a round gate to a square opening because of differential pressure being conveyed. The round shape of the gate’s orifice seals better than a square shape in differential pressure.

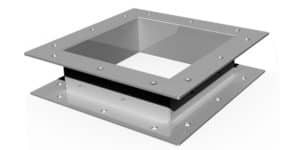

Square to Square Transitions

A square to square transition can be an easy solution if you are replacing existing equipment and need a spacer. Material may be fed by a screw conveyor to a hopper or bin on scales. Typically, the conveyor’s flange would be square, and often there would be a gate below the conveyor to assure positive material shutoff. In this case, a square to square transition would be used between the conveyor flange and the inlet flange of the slide gate.

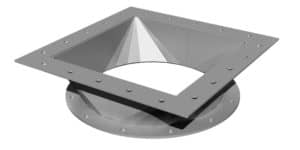

Square to Round Transitions

Square to round transitions may be ordered for square gates where the gate outlet attaches to downstream equipment requiring a round opening (tube stub or flanged). These transitions normally add 4″ to the overall height of standard gate sizes and 6″ or more to the overall height of larger custom sizes. In the same system as mentioned in the square to square transition, the slide gate will usually have a flexible connection to the hopper or bin downstream to allow material in the hopper or bin to be weighed. In this case, a square to round transition would be used to match the square gate to a round tube stub that has a sock bead to connect the conveyor gate to the bin or hopper on the scale.

Another example of using this transition is when an airlock is used in a gravity application. Normally, square slide gates such as roller gates or clear action gates would be placed above the airlocks to handle the abrasiveness of the material being conveyed. If the airlock has a round opening, a square to round transition would be needed to fit the square gate.

In situations where the material conveyed is especially abrasive or sticky, a transition can be fabricated so that the discharge end sets into a gate below that has an opening 1″ larger than the transition. This allows the transition to sit lower into the gate almost touching the blade, where it can serve as a Special Service Inlet.

Flat Flange

A blind transition is a thin piece that can be fabricated three different ways;

- it can be pre-drilled to match the customer’s pattern,

- it can be a “blank” transition with no holes in it so the customer can drill its own holes, or

- it can be drilled to match one piece of equipment and welded to the mating piece of equipment.

Transitions can be fabricated from a variety of materials from stainless steel for sanitary systems, to AR400 steel for abrasive materials. They can also be made from aluminum and carbon steel. Ask your valve manufacturer for the best solution to transition the equipment in your facility.