Client:

Quantity:

Size:

Application:

As Published in Modern Machine Shop Magazine – December 2015 Edition

Shop Invests in Tooling Up-Front, Saves Money in the Long-Run

Saving money by purchasing low-end tooling seems like a simple solution to reduce manufacturing costs. However, that tactic did not work for Vortex, a valve and loading spout supplier based out of Salina, Kansas, USA. The shop realized that poor performance was negating its up-front cost savings, so it contacted Seco Tools, LLC in Troy, Michigan, USA for help. The new Seco tooling helped Vortex save money by reducing tooling inventory and shortening cycle times. It also improved overall part surface finishes.

Vortex works in an engineer-to-order environment in the dry bulk solids material handling industry, producing and selling thousands of valves and loading spouts per year. Each product can weigh anywhere from 10 pounds to 10 tons. According to the company, one of the reasons for this high-mix, low-volume environment is because the application parameters for manufacturers worldwide vary significantly and are virtually endless. Often times, standard products are modified to enhance performance and service life for a specific application. In fact, modified valves make up about 50 percent of the company’s business. The valves are found in food processing plants, airplanes and mines, among countless other manufacturing facilities.

In valve production, Vortex machines a lot of stainless steel and aluminum parts, ranging in size from 0.250 square inch to more than 144 inches long. Machining cycle times can be as short as 30 seconds or as long as three hours, depending on part complexity. On any given day, upwards of 3,000 individual job orders can be circulating simultaneously around 50+ workstations on the shop floor.

In its early days, Vortex outsourced all of its machining work. The company installed its first CNC machine tool in 1991 and since then, has progressively brought part machining in-house. Doing so immediately provided better process control, but Vortex recently realized those machining operations were in dire need of optimization – especially in terms of tooling.

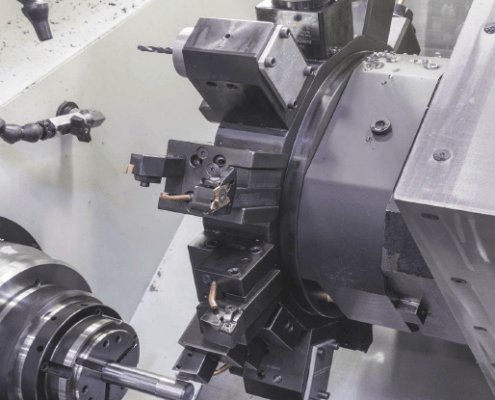

In the past, Vortex ordered low-end tooling from a catalog – without application support from suppliers. Now, Vortex instead reaches out to Seco for its cutting tool needs. Seco evaluated a couple of the shop’s operations and recommended different cutters and inserts that feature advanced geometries and coatings. As a result, Vortex switched all of its high-speed steel cutters to Seco’s Niagara solid carbide-end mills for profiling and contour milling. It also incorporated Seco indexable/inserted tangential milling cutters, multi-directional turning (MDT) grooving and cutoff inserts, and a SecoPoint tool inventory management unit.

The first machine Seco helped optimize was a Hurco vertical machining center (VMC), outfitted with a right-angle head that was slated to run a cast-aluminum part. Vortex specifically added the right-angle head to drill (using an end mill) and profile-mill a particular round part feature. Unfortunately, the shop’s HSS end mills proved to be a huge stumbling block.

“With HSS tools, we were unable to achieve the necessary tool life or cycle times, and surface finish was terrible,” said Jason Bates, machine tool programmer, Vortex. “The Seco Niagara solid carbide-end mills have improved part surface finishes and have boosted cutting speeds and machining step-overs. This has shortened part cycle times by almost 60 percent. These production improvements eliminated the need for a second machine, which we intended to add to keep pace with production. Plus, the Niagara tool cost, while a bit higher, still meshed perfectly with our part-cost expectations.”

The Niagara end mills at Vortex use an extra fine-grain, cemented-carbide raw material that is a true sub-micron-grain tungsten carbide alloy, classified within the C1 to C4 range. As such, the tools provide a combination of toughness and strength, making them well-suited for machining aluminum, stainless steel, titanium and exotic alloy materials.

Seco also helped Vortex optimize grooving and cutoff operations on one of its turning centers. In one application, the company needed to thread, groove and mill a chrome-plated air cylinder shaft that, as a raw piece of material, was induction-hardened to Rc 58-60. Cutting through the hardened part surface proved difficult, and Vortex’s old inserts only lasted for five parts per cutting edge in the grooving operation.

After switching to Seco’s MDT inserts for both grooving and cutoff operations, Vortex was able to increase its feeds slightly, but the biggest gain was in tool life. It now can cut 50 parts per insert edge. Because of this, Vortex switched to Seco MDT inserts for all grooving operations.

The Seco MDT system encompasses holders and inserts for external radial, external axial and internal machining. The tools are well-suited for applications that include turning of parts with many different diameters, complicated profiles and grooves. For Vortex’s complex parts, one Seco MDT tool often replaces several standard and special tools, the company says.

Increasing tool life helps Vortex reduce its overall tooling inventory, as does the shop’s SecoPoint tool inventory management unit. According to Vortex machine shop supervisor Mike Beus, the shop is now ordering about 50 percent less tooling, simply because of better tool-use tracking. SecoPoint dispenses tools one at a time from one location. Now, for instance, whole boxes of inserts are no longer floating around the shop at various workstation benches, going unused.

“Before SecoPoint, we relied on a dry-erase board and would estimate what tools we needed week-by-week – hoping to order enough, but not too much," Beus explained. "Now, we know exactly how many tools we have used, and how many will need to be reordered.”

According to Vortex, the shop never would have been able to truly benefit from its in-house machining operations had it not been for Seco’s advanced tooling technologies and application support. For Vortex, this support comes from Seco technical specialist Troy Jacobson, who often spends an entire day watching a machining operation alongside the machinist to determine how Vortex might make improvements. He comes into Vortex at least once a week to help ensure the shop is using the right tool for the job.